Crystalline Silica is called the “new asbestos” because it shows similar properties to asbestos. It is a naturally occurring mineral found in common industrial and construction materials, which can lead to harmful materials when disturbed. This blog will look into this material through an investigative lens.

Understanding Crystalline Silica

Crystalline Silica is a naturally occurring mineral found in sand, stone, concrete, and mortar. It is a naturally occurring mineral that is commonly used in construction, mining, and industrial processes.

It is often found in both natural and manufactured products. Natural resources that may contain crystalline silica can include rocks, sand, granite, and soil. Meanwhile, manufactured examples such as brick, mortar, concrete, pottery, and ceramics may contain it as well.

When disturbed, crystalline silica can lead to exposure in the form of respirable crystalline forms of silica, which can be about 100 times smaller than ordinary sand particles. And how is this respirable silica dust created? It is created by activities such as abrasive blasting with sand, crushing rock, concrete, or brick blocks, drilling into concrete walls, manufacturing brick, crushing stones, and so on.

Why is Crystalline Silica Dangerous?

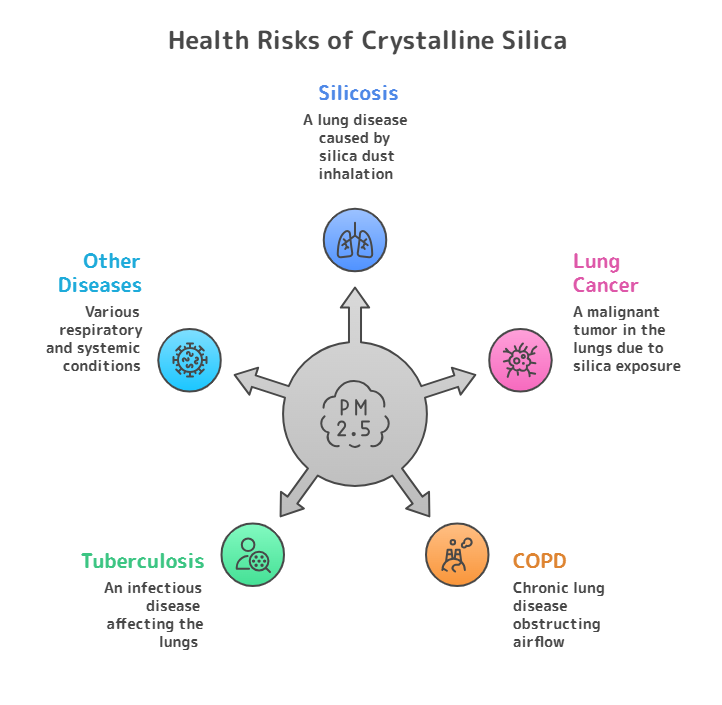

While it can commonly be used in construction and industrial processes, crystalline silica, when disturbed, can create respirable dust that contains very fine particles. This crystalline silica dust, when inhaled, can lead to potentially fatal diseases such as silicosis, lung cancer, chronic obstructive pulmonary disease (COPD), tuberculosis, and others.

And it is this that makes crystalline silica dangerous. Moreover, as exposure to respirable silica dust is common across several industries, including mining, construction, stone cutting, and others, its danger can be considered ever-present.

Breathing in these materials can lead to inflammation and scarring in the lungs, which further increases the risk of various respiratory and systemic conditions. And to understand this further, let’s look into how the exposure occurs. Exposure to crystalline silica dust can occur due to:

- Inhalation of respirable crystalline silica is the primary reason for these diseases.

- High-risk occupations such as mining, quarrying, construction, sandblasting, and the manufacturing of pottery, glass, and ceramics can lead to exposure.

- Household activities like cleaning and laundry can also contribute to exposure.

And who are the ones generally at risk?

Workers in certain industries are at significant risk. Exposure to crystalline silica can cause:

- Mining and quarrying

- Construction and demolition

- Stonework and stone cutting

- Pottery, glass, and ceramic making

- Foundry work and sandblasting

And it is these risks that lead to crystalline silica being renamed as the new asbestos.

Workplace Regulations and Standards

All across Australia, different regulations and exposure standards are maintained to focus on managing respirable crystalline silica exposure. Safe Work Australia has set the workplace exposure standard, in which the Workplace Exposure Standard (WES) has been set at 0.05 mg/m³ as an 8-hour time-weighted average.

Also, effective from July 1, 2024, the key regulation standards in the country have been established, where a ban on the processing and use of engineered stone has been implemented. This is because engineered stone is considered a high-risk material for respirable crystalline silica exposure.

International Guidelines

The International organization, OSHA, has issued two respirable crystalline silica standards. The first one is for construction, while the second is for general industry and maritime.

In terms of construction, the standard makes sure that the exposure should remain below 25 μg/m³ as an 8-hour TWA under foreseeable conditions. This implies that in situations under control, an exposure level below the stated amount can be achieved.

On the other hand, according to research by PubMed, the threshold limit value for respirable silica should be maintained at the ACGIH (American Conference of Government Industrial Hygienists) recommended level of 0.025 mg/m³ for a maximum of an 8-hour workday.

Preventive Measures for Workers & Employers

Other than the exposure standards in the workplace set by Safe Work Australia, OSHA, and others, there are also preventive measures, both in general and in the workplace. And some of the preventive measures considered include:

- Engineered Stone Ban: A ban on the processing and use of engineered stone has been in effect since 1st July 2024. This step is taken to address the high risk of silicosis from exposure to crystalline silica.

- High-risk Processing: Stronger regulations have been put in place for the high-risk processing of materials that contain crystalline silica, which has been effective since September 2024.

- Silica Risk Control Plans: Undertaking a project that risks exposure to crystalline silica substances must be managed by making planned risk assessments.

- Training: Workers who are involved in projects where they are at risk of exposure must receive additional training on control measures, using them, and on possible health risks.

- PPE: Using Personal Protective Equipment or PPE is crucial for workers at high-risk sites.

- Air Monitoring: Crystalline silica air monitoring is essential in specific work sites where risk of exposure is high, to understand how badly the air is contaminated with respirable crystalline silica dust.

Crystalline Silica vs. Asbestos: The Growing Concern

Thus far, we have evaluated the reasons that make crystalline silica be referred to as the new asbestos. However, how does this damage compare to asbestos exposure? Let’s look into that with the help of the following chart:

| Factors | Crystalline Silica | Asbestos |

|---|---|---|

| Source | Naturally occurring mineral found in sand, quartz, stone, concrete, and bricks. | Naturally occurring fibrous silicate minerals used in construction and insulation. |

| Common Uses | Construction materials (concrete, tiles, engineered stone), mining, and manufacturing. | Insulation, roofing, flooring, cement products, automotive parts (before bans). |

| Exposure Pathway | Dust released during cutting, grinding, drilling, or crushing materials. | Fibres released when materials are disturbed, damaged, or deteriorating. |

| Primary Health Risks | Silicosis (incurable lung disease), lung cancer, COPD, and kidney disease. | Asbestosis, mesothelioma (rare cancer), and lung cancer. |

| Latency Period | 10–30 years for a serious illness to develop. | 20–40+ years for illnesses like mesothelioma to appear. |

| Regulatory Status | Increasingly regulated (exposure limits in workplaces), but still widely used. | Banned or strictly restricted in most countries. |

| Level of Concern Today | Rising concern as cases of silicosis increase, especially in the stone benchtop industry. | Well-known hazards, historical legacy issues persist in older buildings. |

| Prevention Measures | Dust suppression (water, ventilation), PPE, air monitoring, and worker training. | Asbestos disposal, encapsulation, strict handling/disposal laws. |

| Public Perception | Emerging recognition as a “new asbestos” due to similar health impacts and a delay in regulation. | Established as a notorious industrial hazard with strong public awareness. |

Table: Crystalline Silica vs. Asbestos

So, to reiterate, crystalline silica has been drawing parallels with asbestos due to certain reasons. These reasons often include the ubiquitous use in construction and other projects, delayed symptoms, as well as long-term exposure leading to risks that can be fatal as well.

More or less, the significance of the name, “New Asbestos”, also comes from the fact that after asbestos usage was banned, crystalline silica became more common, and eventually, investigations led to concerns being raised due to silica.

Thus, lessons need to be learned from asbestos exposure, and it will be crucial to remediation and prevention in the case of crystalline silica exposure.

Summing Up

Crystalline silica poses risks that have been compared to asbestos. Therefore, awareness, regulation, and prevention are crucial to protect workers and the public. This implies that the issue needs to be taken seriously. Treating it seriously today can help avoid tomorrow’s health crisis.

Concerned about Crystalline Silica Exposure? Here’s What to Do!

If your workplace or project involves cutting or grinding stone, tiles, or concrete, ensure compliance with safety standards and protect your team from silica dust exposure. Or consider the aid of a top remediation consultant. Their expert-level support can be critical for your long-term protection, be it personal or in the workplace.

Frequently Asked Questions

What Are Some Common Prevention Measures for Respirable Dust Particles Becoming Airborne?

There are certain methods that you can apply when at a site with silica exposure risk. You can apply water to dusty surfaces to help prevent the dust from going airborne.

What Are the Usual Symptoms of Silicosis?

The symptoms of silicosis include a long-lasting cough or a persistent shortness of breath, and both could be accompanied by the inflammation of the airways. Scarring in the lungs can also be a key indicator.

Is Silicosis Completely Incurable?

Yes. Silicosis is generally incurable. The treatment generally focuses on managing the symptoms and providing supportive care to help patients cope with them.

Is Crystalline Silica More Harmful Than Asbestos?

That is not necessarily the case. Both can be slow-acting toxins and can also lead to major, incurable diseases with long-term harm to the respiratory system.