In industrial and construction settings, noise monitoring is necessary for ensuring worker safety, regulatory compliance, and community relations. Today, technologies like cloud computing, Internet-of-Things (IoT), and Artificial Intelligence (AI) have enabled real-time remote monitoring, automated alerts, and predictive analysis. And this has enhanced the efficiency of noise monitoring.

Choosing between a stationary and portable system is essential for meeting project-specific data accuracy and flexibility needs. If you want to know more about the choice between fixed and portable noise monitoring, keep reading.

Understanding Industrial Noise Monitoring

If you are running a busy industrial operation, noise is not just a by-product. It is a major safety and compliance issue. In relation to this, industrial noise monitoring is the process of tracking sound levels to protect workers and the company’s public image. Industries rely on noise monitoring to meet strict regulatory compliance, which is often mandated by standards like OSHA, ISO, or Australia’s AS.

Wondering why environmental noise monitoring is so important? Because excessive noise can cause permanent damage. It can affect the hearing of workers and also disturb nearby residents. So, you are required to assess exposure limits continuously. From construction and mining to manufacturing and transport, reliable environmental noise monitoring is non-negotiable.

What Are Stationary Noise Monitoring Solutions?

Let’s understand what fixed noise monitoring systems are.

Overview

Think about a permanent guard who is watching your site 24/7. A stationary noise monitoring equipment is a permanently installed system that is generally hardwired and connected directly to your network. Such a continuous setup allows effortless streaming of data back to a central server, which ensures that critical noise events are never missed.

Key Features

The greatest selling point of stationary systems is automation. The fixed systems provide real-time data. So, you don’t just get to understand what happened, but also what is happening at the moment.

The systems can automatically alert you instantly via email or text if noise exceeds a pre-defined threshold. Moreover, sophisticated fixed systems are also designed for deep integration with environmental management systems. So, they can provide you with seamless compliance records and operational insights.

Ideal Use Cases

You must go for stationary monitoring systems if you need long-term assurance. They are perfectly suited for major infrastructure like airports, manufacturing plants, and large-scale urban development projects. This is because continuous mitigation of public-facing noise is extremely important, as regulatory scrutiny remains constant.

What Are Portable Noise Monitoring Solutions?

Let’s see how a portable system is different from a stationary one.

Overview

A portable noise monitor is great for short-term auditing. These are lightweight, mobile systems that can be deployed rapidly. So, they are useful in quick surveys or projects spanning across several locations. Flexibility is the core value that the portable systems offer. You can move them easily with changing operational needs.

Key Features

Portable noise monitoring systems are not dependent on power outlets. They are battery-powered devices with long runtimes. Built-in GPS-enabled functionality further enhances their mobility, as they can automatically log the precise location of every reading taken.

The main advantage of portable systems is the ease of deployment. It can be easily set up and quickly retrieved by a technician. So, you can get results for a specific noise concern immediately, without requiring permanent changes to infrastructure.

Ideal Use Cases

A portable noise monitoring equipment can be used if you need a spot assessment of a new piece of equipment. You will also find portable systems useful if you are managing a short-term construction phase that will only last for a few weeks.

Portable solutions are ideal for tasks like troubleshooting, temporary monitoring, and compliance checks across a diverse portfolio of sites. Portable noise monitoring solutions are essential in sites where permanent installation is not practical or cost-effective. So, contact us for a hybrid noise monitoring system for your site today!

How to Choose the Right Noise Monitoring System

Here is how you can choose the right noise monitoring system.

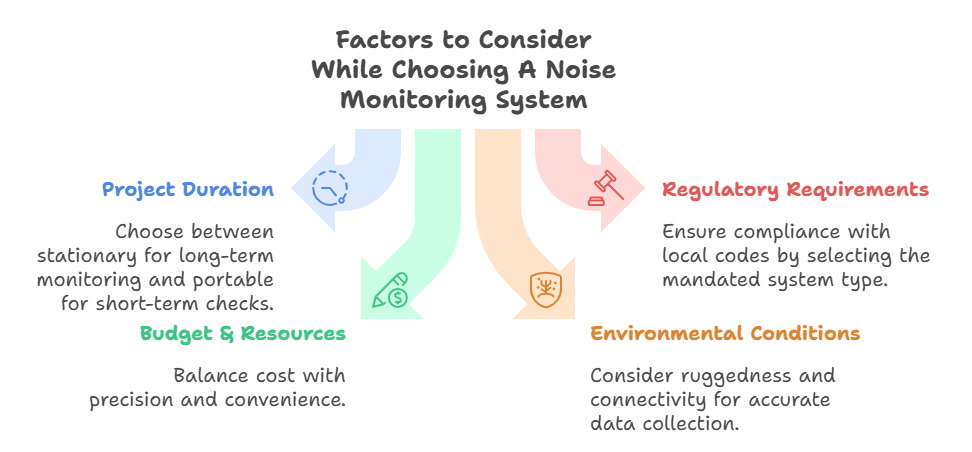

Based on Project Duration

Are your noise monitoring needs continuous and long-term? Then go with a stationary system for automation and integration. And if you only require a noise monitoring device for investigative checks or for a short term, go for a portable system.

Based on Regulatory Requirements

Sometimes, the law will decide the type of noise monitoring system you must use. Check if permits or local codes explicitly make it mandatory to have fixed boundary monitoring near residential zones.

Based on Budget & Resources

Precision and convenience come at a price. A stationary system will require higher investment but allow precise, continuous, and long-term monitoring. Conversely, portable systems offer convenience, mobility, and immediate accessibility.

Based on Environmental Conditions

The environment in which you need to monitor vibrations will decide the ruggedness and connectivity required for the system. Stationary noise monitor systems are designed for maximum durability and reliability over long periods. They come with weatherproof housing and tamper-proofing features, which ensure that data is collected continuously and accurately even in demanding conditions.

Combining Stationary and Portable Solutions for Complete Coverage

A hybrid model can greatly optimize your acoustic performance. A stationary system can establish a reliable baseline. So, you will get the necessary legal documentation for your perimeter 24/7. On the other hand, portable units serve as flexible and tactical tools. You can deploy one inside your perimeter to further validate the readings from the fixed systems.

Hybrid systems help pinpoint the sources of operational noise, especially the ones causing high-level noise. By combining stationary and portable types, your organisation can achieve superior data resolution. You will have a much clearer picture of your operations, which will ultimately ensure full safety and compliance of your site.

Stationary or Portable? Or Ready for a Hybrid?

The choice between a stationary and a portable system comes down to permanence versus flexibility. Fixed systems are more suitable for continuous monitoring and automated data collection. They are more precise, durable, and compliant.

Portable systems are agile tools that are more suitable for site-specific diagnostics. They offer great mobility and flexibility. Ultimately, smart monitoring guarantees regulatory compliance, enhances worker safety, and supports informed business decisions. And if you go for hybrid systems, you can benefit from the strengths of both types while complementing the shortcomings. So, contact us for a hybrid noise monitoring system for your site today!

Frequently Asked Questions

How Often is Industrial Sound Monitoring Required in Australia?

Industrial noise assessments must be done at least every five years. It must also be done whenever changes occur in the plant, work processes, or building structure. Initial and subsequent audiometric testing must be provided for workers requiring hearing protection. You must start it within three months of commencement, and at least every two years thereafter.

Can Industrial Noise Levels Affect Manufacturing Processes?

Yes, excessive industrial noise can negatively impact processes by causing stress, fatigue, and impaired concentration among workers. This can lead to an increase in the rate of errors, while tasks take more time to complete. Mechanical vibrations can also cause equipment malfunction and structural fatigue, which can raise your maintenance costs.

What is the Allowed Range for Industrial Noise in Australia?

Workers must not be exposed to a noise exceeding an average of 85 dB over an eight-hour shift. Similarly, they must also not be exposed to a maximum (peak) noise level above 140 dB. If combined with exposure to ototoxic substances, the 85 dB average standard limit is reduced to 80 dB.

How Can I Minimise Industrial Noise Levels?

Industrial noise levels can be minimised by following the hierarchy of control. First, eliminate the noise source if possible, or substitute it with a quieter plant or process. Next, use engineering controls like acoustic enclosures, sound-absorbing materials, and vibration damping. Also, ensure that all equipment is regularly maintained.